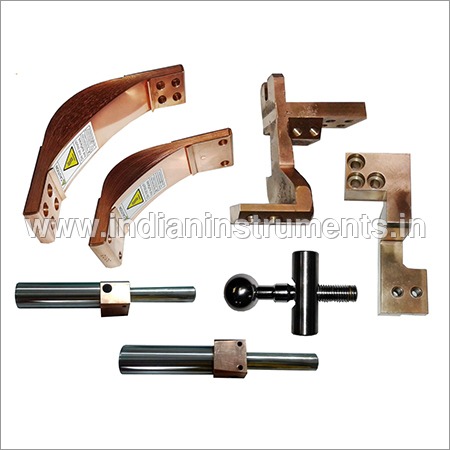

Cap Tip Opener

Cap Tip Opener Specification

- Frequency

- 50Hz

- Application

- Opening welding cap tips

- Phase

- Single Phase

- Automation Grade

- Semi-Automatic

- Power Source

- Electric

- Output Voltage

- 24V

- Current Range

- 0.5A-2A

- Equipment Type

- Cap Tip Opener

- Welding

- Manual/Automatic

- Diameter

- Tip size 12mm - 18mm

- Power Consumption

- Low

- Type

- Cap Tip Opener

- Condition

- New

- Motor Type

- Electric

- Material

- Metal

- Power

- 120W

- Voltage

- 230V

- Dimensions

- 320mm x 150mm x 250mm

- Input Voltage

- 220V

- Rated Current

- 0.54A

- Rated Capacity

- 1-5 pieces/minute

About Cap Tip Opener

Keeping in mind ever-evolving requirements of our valuable clients, we are offering an exclusive range of Cap Tip Openert. The offered cap tip opener is developed at our end using top quality components and advanced technology, in fulfillment with set standards of industry. We provide this Cap Tip Opener at nominal rates in a given time frame. This cap tip opener is valued in the industry due to its excellent finish & unmatched quality.

Features:

- Perfect design

- Fine finish

- Compact structure

- Long working life

Designed for opening Variety of Cap Tip Shapes.

Easy to use, Light weighted and handy.

Reduces wastage of time while removing cap tips.

Helps to avoid accidents.

Universal design to open from M-13 D to M-22 D.

Available in Dual Models: Individual Cap Tip Opener, & Universal Model.

Efficient and Reliable Workshop Tool

The Cap Tip Opener boosts productivity in industrial and automotive workshops by opening welding cap tips quickly and safely. Its semi-automatic operation helps reduce manual effort, while its overload protection enhances workplace safety. The powder-coated metal body offers resilience against wear, and the devices compact dimensions make it easy to fit onto benches without occupying excess space.

User-Friendly Operation and Maintenance

Designed for intuitive use, this opener is activated through a footswitch control, allowing operators to work hands-free. With low maintenance requirements and a portable 9 kg build, users benefit from significant time and cost savings over the products lifetime. Its low noise level ensures a comfortable working environment, even during peak usage.

FAQs of Cap Tip Opener:

Q: How do I operate the Cap Tip Opener using the footswitch?

A: To operate the Cap Tip Opener, connect it to the power supply and position it on a stable bench. Place the welding cap tip in the holder and use the footswitch to initiate the opening process. The device will open up to 8 tips per minute, allowing for efficient workflow.Q: What is the primary application of this Cap Tip Opener in workshops?

A: This equipment is primarily used for opening welding cap tips, making it ideal for industrial and automotive workshops where frequent tip changes are required during welding processes.Q: When should the overload protection feature be used?

A: The overload protection automatically activates if the device encounters excessive force or an obstruction while opening cap tips, preventing damage to both the equipment and the operator. No manual intervention is required for this safety feature.Q: Where is this Cap Tip Opener suitable for installation?

A: Its bench-mounted design and portable size make it suitable for installation on workbenches in industrial or automotive workshop environments. Its compact footprint ensures it does not take up excessive space.Q: What are the maintenance requirements for this equipment?

A: The Cap Tip Opener requires only minimal maintenance due to its robust construction. Routine checks for wear and occasional cleaning of the powder-coated surface will ensure long-term reliability.Q: How does the semi-automatic operation benefit users?

A: Semi-automatic operation allows users to process multiple tips hands-free via the footswitch, reducing fatigue and increasing productivity. It combines manual control for flexibility with automation for consistent results.Q: What sizes of welding cap tips can the opener handle?

A: The device accommodates welding cap tips with diameters ranging from 12mm to 18mm, making it versatile for a variety of industrial cap tip sizes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Machine Parts Category

Portable Spot Welding Gun

Material : Highgrade Copper and Steel

Type : Portable Spot Welding Gun

Condition : New

Automation Grade : Manual

Dimensions : Compact size for portable use

Application : Industrial Spot Welding

Pneumatic Tip Dresser

Material : Hardened Steel

Type : Pneumatic Tip Dresser

Condition : New

Automation Grade : SemiAutomatic

Dimensions : 430 mm x 180 mm x 140 mm

Application : Dressing and maintaining welding tips

IT Gun Spares

Material : Copper and Stainless Steel

Type : Gun Spares

Condition : New

Automation Grade : Manual

Dimensions : Custom Size

Application : Welding Equipment

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry